As a printer with 30 years of experience of the industry here is a simple explanation of the price difference between lithographic (litho) print and digital printing and thus why they are used for different things. Some years ago, it was said that lithographic was used whenever a quality product was required. However, whilst litho is still the gold standard for print quality, digital has improved so much that most would struggle to see the differences in print quality. Now the principal difference is the economics of the two print methods

Summary

- Litho uses a plate from which to print resulting in high set up costs

- Litho uses larger paper sheets with multiple pages printed at a time, so lower run on costs

- Digital has little set costs

- digital is best for print on demand up to around 100 copies

- Litho much cheaper for long runs

The Basics of Litho Printing

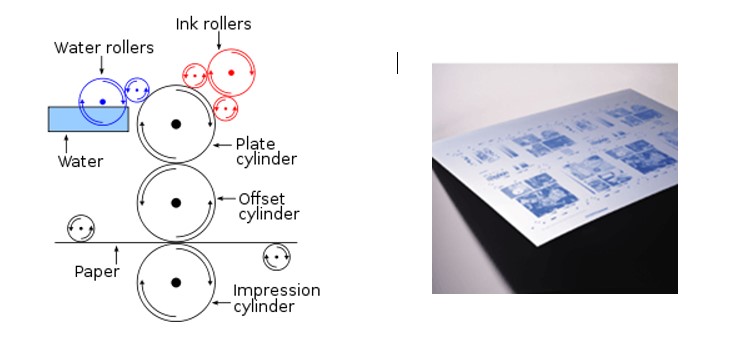

This is not meant to be a full explanation of the litho process – others can do that - but it is important to know that litho processes begin with creating a plate for each of its colour stations. The plate is either aluminium or a polymer which is etched by laser with the image

The plate must be loaded to the plate cylinder and using a liquid alcohol based ink the image is transferred via an offset roller to the paper. Thus before the first copy of the print run is created there is a substantial setup required for litho printing resulting in higher initial costs.

Litho presses are generally much larger than digital presses with a paper sheet size of B1 or B2 – that means it can print 8 or 4 x A4 images at a time (for B1 and B2 respectively). Thus, the run-on costs are lower, making it cost-effective for larger print runs.

Digital Printing: A Closer Look

Digital printing, on the other hand, is akin to having a laser printer but on a much larger scale. It employs a single roller, negatively charged, to use electrostatic forces for toner transfer. The laser creating the image, creates the image afresh with each print and the toner once transferred is fused in place with heated rollers.

Thus there is no printing ‘set-up’, nor costs associated. The running costs remain consistent and are higher than for lithographic.

Comparing Cost Dynamics

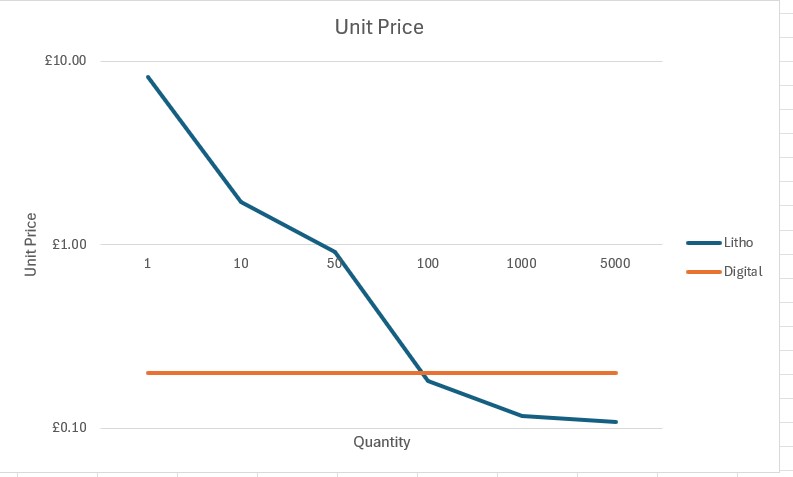

| No Of Prints | Digital | Lithographic | ||||

| Total | Unit | Total | Unit | |||

| 1 | £0.2 | £0.20 | £81.00 | £81.00 | ||

| 10 | £2.0 | £0.20 | £82.00 | £8.20 | ||

| 50 | £10.0 | £0.20 | £86.00 | £1.72 | ||

| 100 | £20.0 | £0.20 | £91.00 | £0.91 | ||

| 1000 | £200.0 | £0.20 | £181.00 | £0.18 | ||

| 5000 | £1,000.0 | £0.20 | £581.00 | £0.12 | ||

| 10000 | £2,000.0 | £0.20 | £1,081.00 | £0.11 | ||

The difference in cost trends between digital and litho printing is significant. With digital, the cost per unit is the same whether you're printing ten copies or a hundred. In contrast, though litho printing has a higher initial setup cost, the expense per unit drops sharply with increased volume. As you can see in the graph, once you reach 100 to 150 copies, litho printing becomes the more economical option.

Choosing the Right Technique for Your Needs

This economic distinction is a key in choosing between digital and litho printing. For short runs, where only a few copies are needed, digital is the more practical choice. However, for longer runs, litho stands out as the cost-effective alternative due to its decreasing unit cost with higher quantities.

When it comes to printing, knowing the strengths and cost dynamics of digital and litho printing can guide you toward the most efficient choice for your project's needs.